Project Review & Viability Analysis

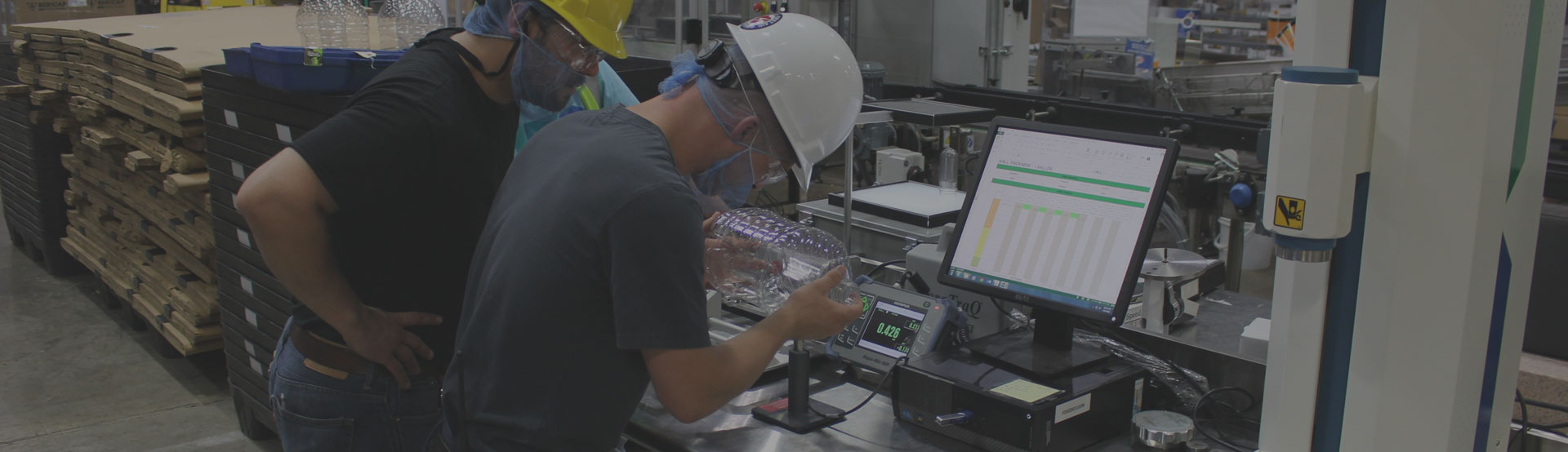

Get an outside, objective assessment of the viability of your project before you invest hard dollars in machines and processes. Make sure your production line is as efficient as possible and will deliver acceptable end results prior to production.- Neutral observers objectively identify areas for workflow improvement, and pinpoint any potential issues or gaps in processes to reduce production costs and defects without prejudice towards a particular brand or vendor.

- Evaluation and matching of product specifications to materials for maximum performance and durability

- Development of standards to increase production efficiency and quality control