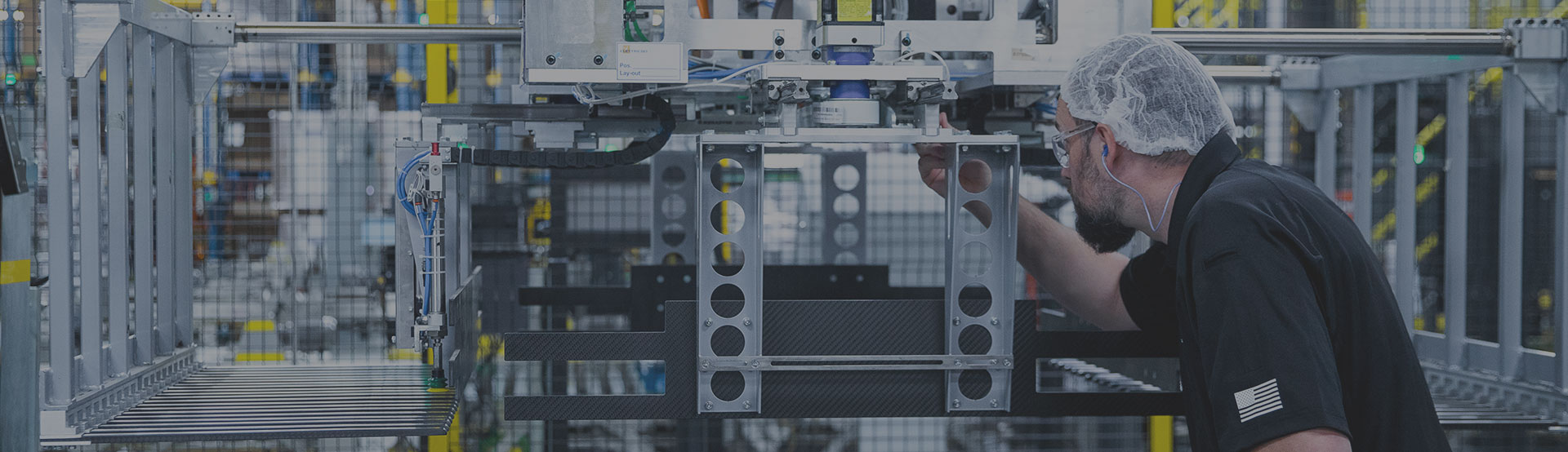

Systems & Process Development

Automated mass production requires a number of systems, processes, and procedures all operating in harmony to assure high efficiencies, maximum throughput, and consistent quality for repeatable results. Leverage our lean six sigma approach and decades of experience to help create, improve, and implement your systems and processes.

Design and implementation of end-to-end production systems and workflows that fulfill manufacturing objectives.

Development of industry-standard production procedures to improve process control and output consistency.

On-site or remote training to educate your team on system capabilities, operation, and maintenance procedures.